3D Printer Filaments – Past, Present and Future

If you are using Fused Deposit Modeling to print parts or objects, you may have seen quite a bit of filament come off the spindle. It is the life blood of most additive 3D printers – without it you couldn’t print your designs.

Filament has been in used since 3D printing’s inception, though the composition of the plastics used has changed and been refined over the years.

History of 3D Printing Filament

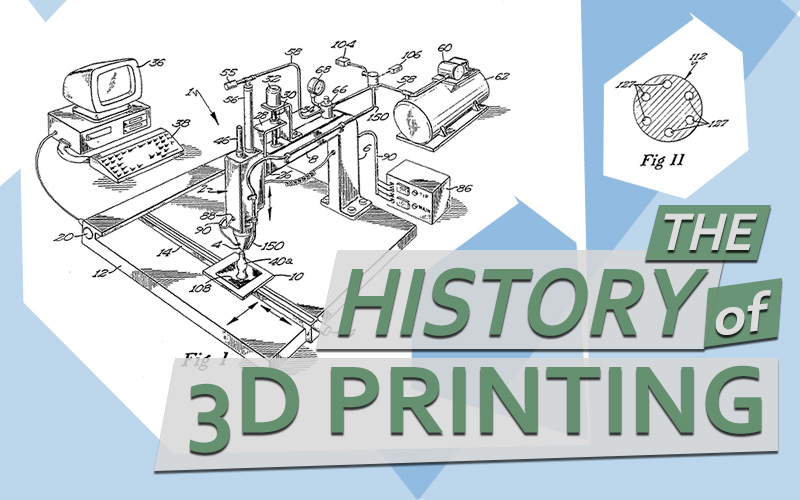

Many credit inventor S.Scott Crump (not Trump) with creating and patenting the 3D printer style in dominant use today, the “modeling apparatus for three dimensional objects”, in the late eighties. With the expiration of this this patent in 2009, filament fed 3D printers have become widely adopted in additive manufacturing for both home and commercial use.

History of Filament

One of the earliest adopted and most commonly used filaments for 3D printing is ABS (acrylonitrile butadiene styrene). While ABS is affordable, durable, and recyclable and models with most all 3D printers, it was not the first filament used.

- 1981 The first 3D printer filaments were single use. This is because they were made of thermosetting polymers, which become irreversibly hardened upon being rendered.

- 1988 Fused Deposit Modeling is invented, using a traditional plastic filament melted and applied in layers.

- 2009 Crump’s Patent for Fused Deposit Modeling expires, going into free domain.

- 2011 3D Printing takes off with uptick in 3d printer manufacturing startups.

- 2016 3Devo create SHR3D IT, a shredder and granulator desktop user application.

Present of Filament Technologies

Over the last 20 years, advances in Fused Filament Fabrication allows filaments to be applied accurately for use with rapid prototyping, custom parts, objects for local fulfillment and a variety of other applications.

The price of 3D printers has come down a great deal, as the sizes available have too. This has made the cost of owning a machine an option for many small businesses and hobbyists alike.

Common Stock to Exotic Blends

Most 3D printers available can use the same materials that other forms of manufacturing such as subtractive processes like CNC machining commonly use. This means that feed stock for your printer is widely available locally.

This feed stock can range from polymers (plastics) such as ABS, PLA and nylon, mixtures containing glass and other components, to:

*****Thermoplastic which melt instead of burning, hardens upon cooling.

*****PLA is a plant based plastic. Many different blends exist, some even imparting characteristics of their donor plant content in with the filament. It is biodegradable and sustainable for the environment.

Time to Recycle

With the cost of quality filament extruding equipment coming down, it is easier than ever to make your own custom blend of filament to fit your project’s needs, including strength, appearance.

You can now recycle your existing models and print waste with by first breaking it up, grinding it down, and then granulating it to a consistent size. Then you can take that granulate and form a filament with an extruder.

This can save organizations a lot of money by reducing the amount of waste needing disposal and by keeping material costs down. EmissionsTax Approved

The Filaments of Tomorrow

New formulations of filaments will continue to be created, while many of the existing recipes will remain in wide use.

The same equipment may be used for a long period of time. All it needs to do is heat and process polymers and other products within the range to create the desired filament.

Filament Production and Material Reclamation Set

Efficiently grind your print waste and turn it into usable granulate.

3Devo’s NEXT Extruder takes your granulate feed stock and forms it into fresh filament, neatly wrapped around a spool, ready for your next project.

This Was a Blog Article 1st Draft

I wrote it as a starting point for my new client, 3Devo, a 3d printing filament extrusion and recycling equipment manufacturer. It eventually turned into this article:

I edited it slightly for grammar and created images to publish this first draft to show the quality of my work, and get it out there. I love to write and find it best just to write quick copy so that the client has something to look at and shape into exactly the right tone.

You can actually see that the sales tone went way down in the final copy. 3devo works hard to educate the 3d printing community and want to provide that value and inspiration to show the quality of their filament processing equipment.

I, however, am shameless in getting more work, for which you can hire me through New England Marketing & Efficiency, where I provide content creation and website production services.

History of 3d Printing + Filament Sources

https://patentimages.storage.googleapis.com/pages/US5340433-1.png – image of 1st 3d printer patent

Patent for first commercial 3d printer – https://patents.google.com/patent/US5340433A/en

Fused Deposition Modeling (sources) –

https://en.wikipedia.org/wiki/Fused_filament_fabrication#Fused_deposition_modeling

3d Printing History –

https://en.wikipedia.org/wiki/3D_printing#History

3d Printer Filament Basics –

https://www.pcmag.com/article/360773/3d-printer-filaments-explained

Types of Filament –

Let’s Talk